Engineering & Aesthetics

Vault of Heaven at the Venice Biennale

in Venice

Curated by architect Ma Yansong, the China Pavilion at the 2025 Venice Architecture Biennale is currently on view at the Arsenal in Venice. Titled “CO-EXIST”, the exhibition runs from May 10 to November 23. bespoke. collaborated with Zigeng Wang—Associate Professor at the Central Academy of Fine Arts School of Architecture and Principal Architect of PILLS —on the China Pavilion installation “Vault of Heaven”. The work reflects the architect’s imaginative interpretation of Eastern traditional culture. Set against the backdrop of China’s rapid urbanization, the installation uses green construction safety nets—ubiquitous at building sites across Chinese cities—as its primary material, interwoven with traditional bamboo weaving techniques, a form of intangible cultural heritage, to create a contemporary reinterpretation of the Zaojing, the ornate coffered ceiling found in classical Chinese architecture.

As the structural consultant for the project, bespoke. brought together structural engineering expertise, aesthetic sensibility, and on-site execution capabilities to oversee a wide range of responsibilities—including structural design, façade design, kinetic structure concept and development, factory fabrication and inspection, on-site assembly, and technical coordination. Through this comprehensive involvement, bespoke. provided solid support for the realization of a dynamic installation imbued with profound Eastern spirit and cultural symbolism, ensuring its precise execution from concept to completion and enabling a full interpretation of the Eastern philosophy of harmonious coexistence between humans and nature.

1 ⁄ 三层结构

Structure: 3 Layers

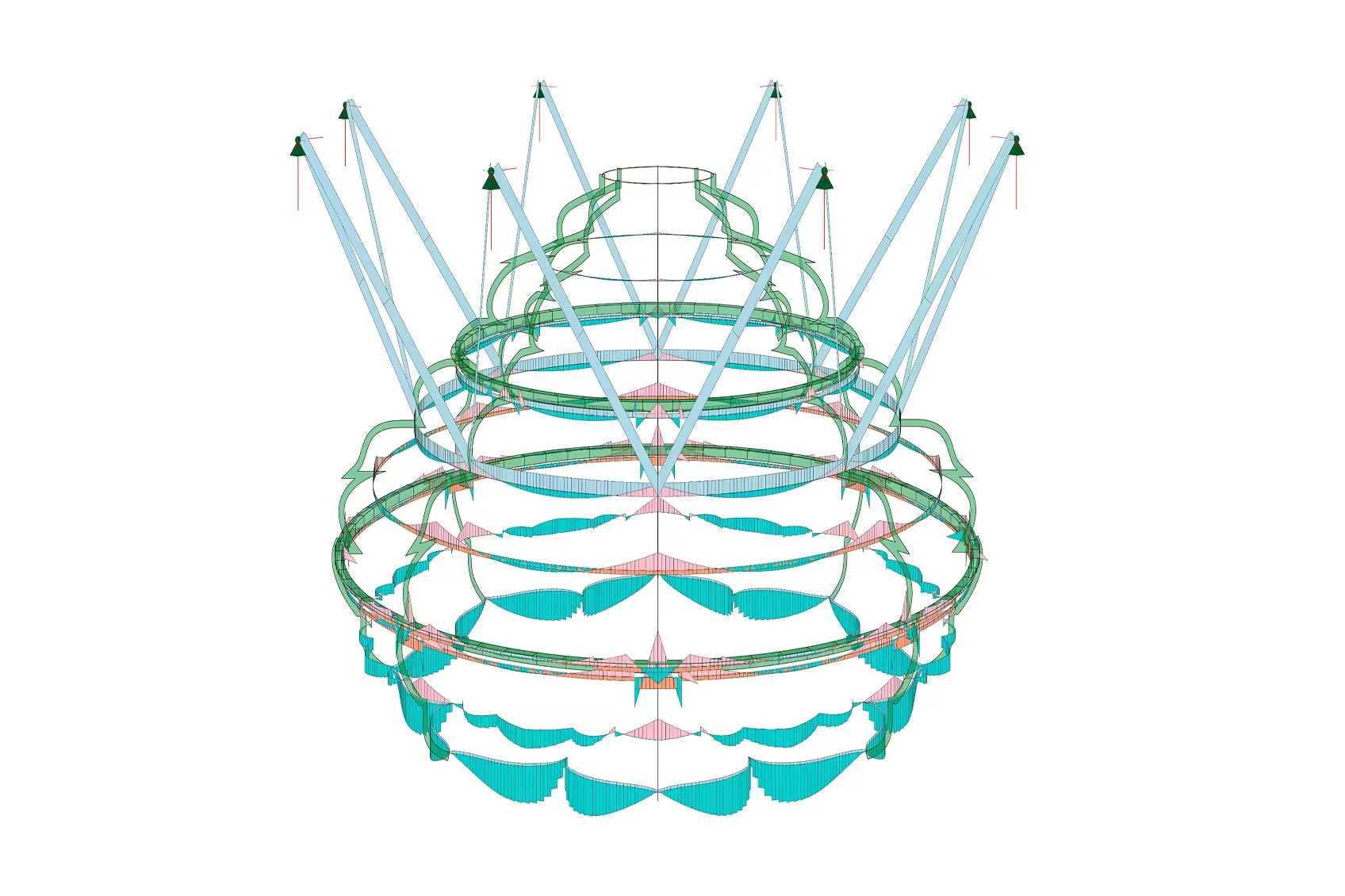

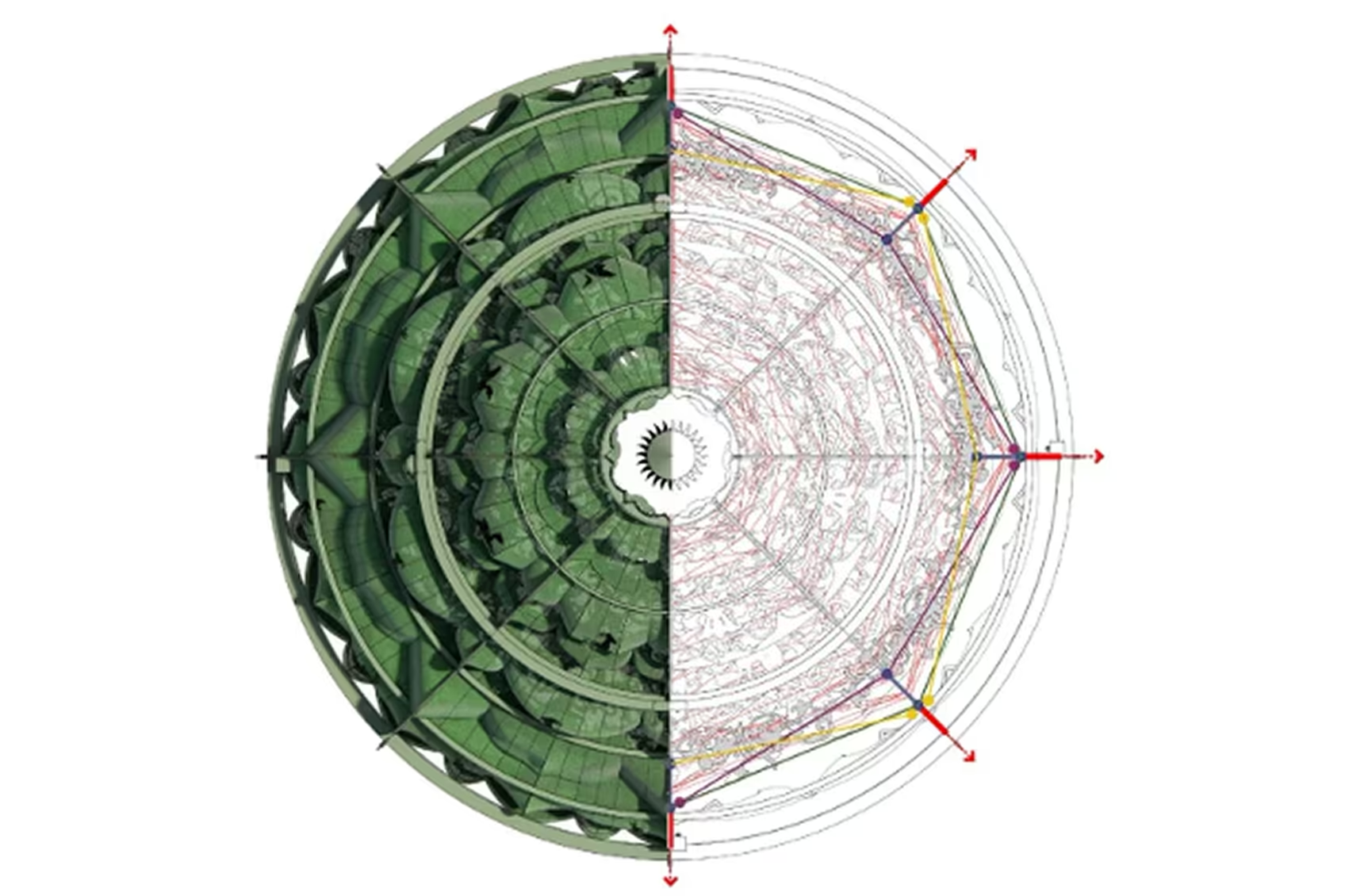

The structure of the installation is composed of 3 layers that work together to create the effect of a whole piece. Because of its complex kinetic nature (described in detail later in the next chapter), each layer is intrinsically joint together and is dependent on each other.

The whole piece is suspended by a series of 8 pairs of V cables. The middle layer is fixed, the top layer is resting on it, and the bottom layer is suspended from it.

The structure layout of the 3 parts has been carefully studied to ensure structure stability and ensure clear force flow transferring between top / middle / and bottom parts. Even though structure is rotating, the point of contacts to the central part remains same and the weight of the top and bottom parts are always transferred to the primary members of the central part, where the suspension V cables are connected.

The structure is composed of a single layer reconstituted shell made of aluminum plates assembled together. Aluminum has been chosen for its good mechanical properties, easy fabrication and lightweight. Indeed, due to constraints of the historical site, the whole weight of the installation has been controlled to less than 400 kg. The inner side of the installation reveals multitude layers of characters, animals and shapes that are positioned in order and with special relation with each other.

A total of 17 layers are positioned inside the installation, each of them revealing more and more details as you spend more time looking at it. In order to achieve the desired floating effect from the designer, a special design inspired by stadium structures has been integrated, while the finest details were used to ensure visual integration with the overall scale of the installation.

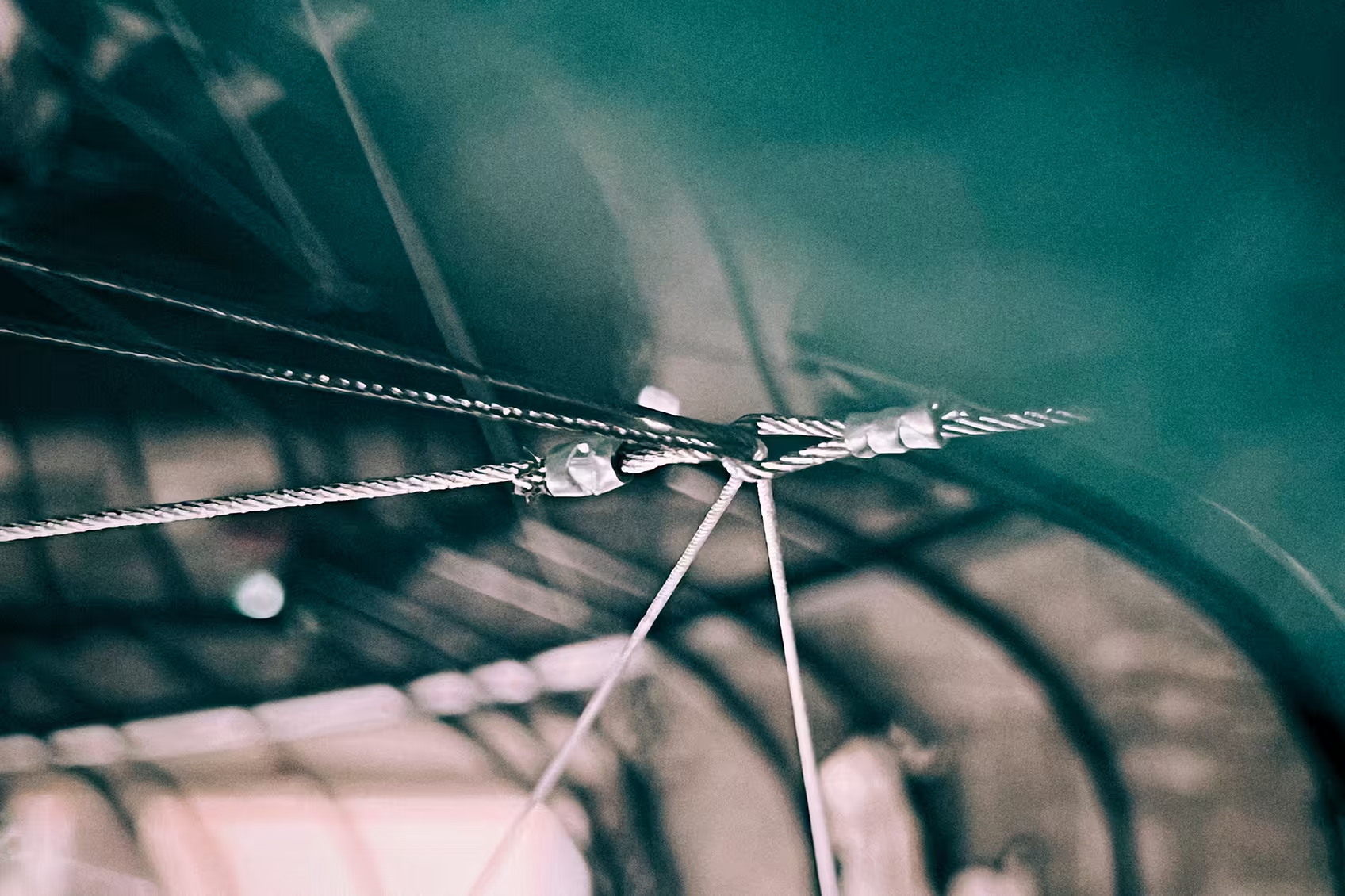

Similar to a stadium kind of structure, the internal sets of ring cables are put in tension with a series of tensers and connected to the main aluminum frame by 8 radial cables (1.5mm diameter stainless steel cables). The tension from those cable networks and radial cables is then transferred as a compression force within the concentric rings of the main aluminum frame skeleton.

The tension and compression forces present in this installation are not directly visible but crucial to the overall stability of the structure.

2 ⁄ 动态美学

Kinetic Elegance

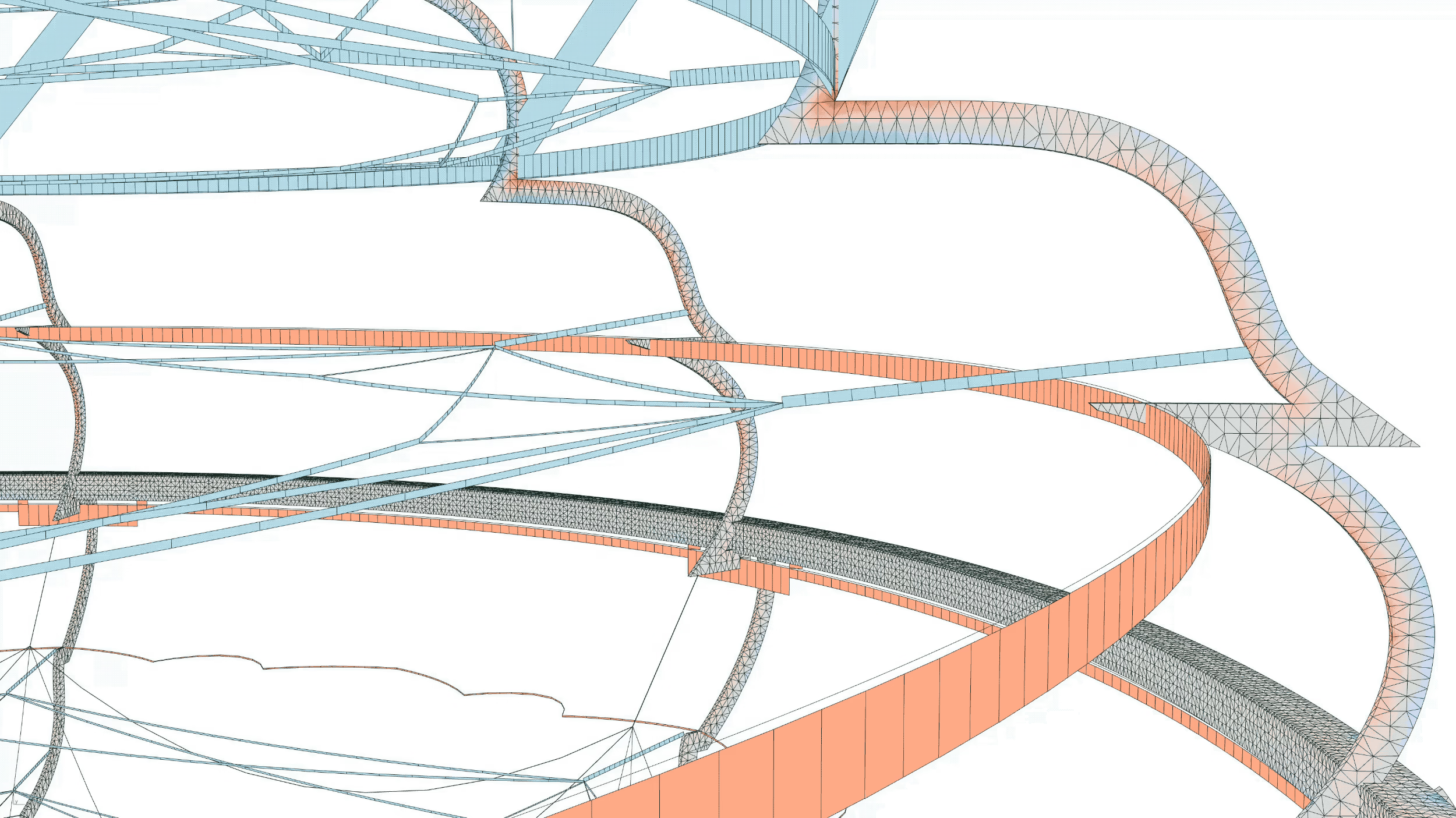

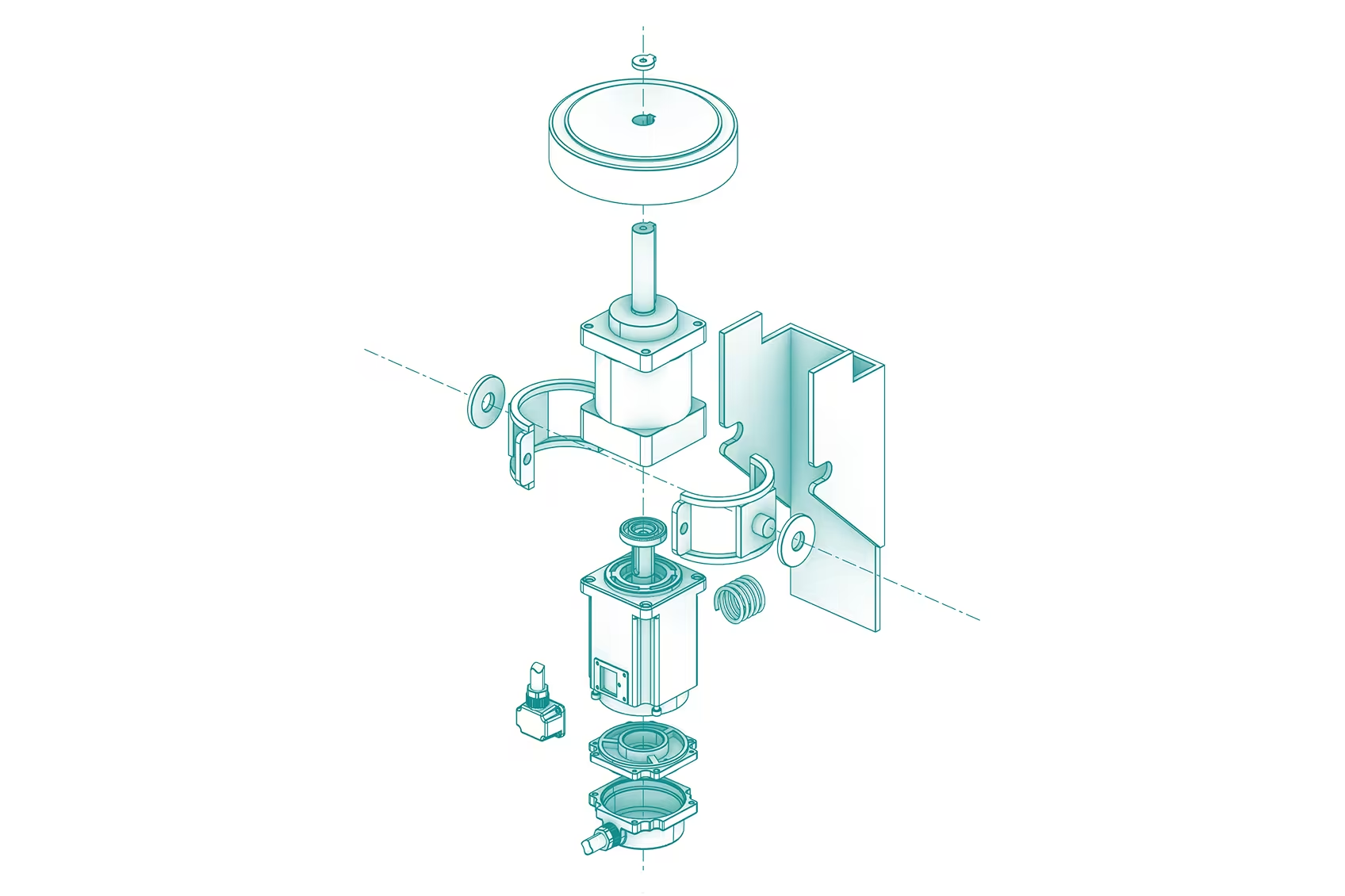

The kinetic aspect of the installation is one of the most important aspects of it. The simple rotation of the top part and bottom part makes the whole installation concept alive while it also brings many technical challenges that need to be resolved. Here are some secrets about the concepts and design of the kinetic.

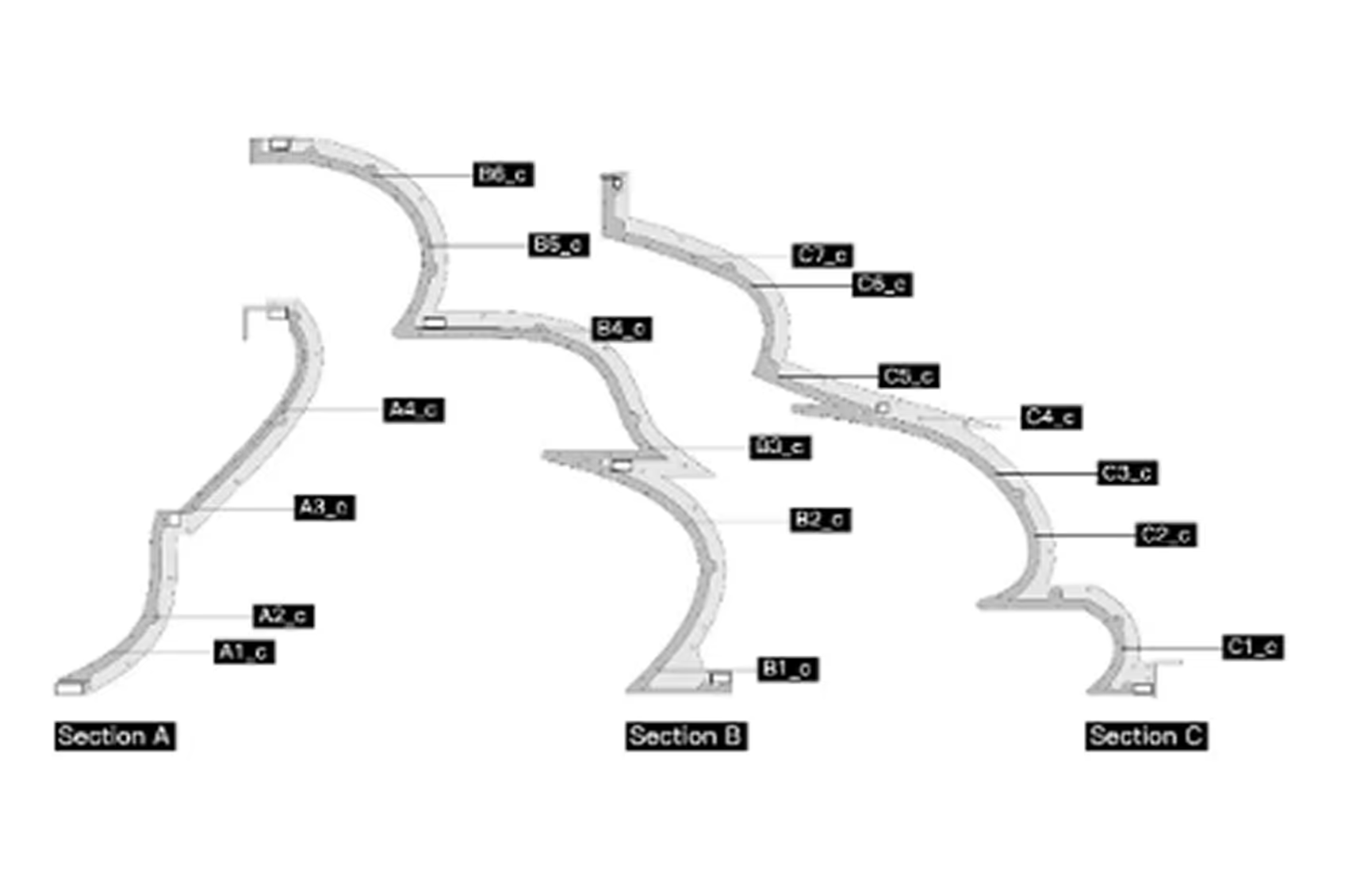

The design of kinetic parts in an installation requires very high fabrication precision and high craftmanship capability to ensure all pieces fit well together. When the overall size of the elements is big, as it is the case with our installation (up to 5m in diameter), this required precision is even more difficult to achieve. All the pieces in our structure have been laser cutes to match perfectly the 3D design model.

Due to very tight spaces between each component to keep the design of the structure as compact as possible (talking of few mm spaces) , some connection plates used during the assembly of the 8 modules of each part have been designed to ensure the "perfect" concentric geometry of the parts.

After ensuring "perfect" geometry is achieved, the method to make top part and bottom part rotate were then applied. We choose to use friction wheels instead of mechanical way to transfer movements from one element to another. Some key aspects of this choice were to apply a "soft" transfer of energy between the rubber wheels and the aluminum components and also avoid having parts that can break due to some potential unwanted structure displacement and self-locking of the mechanism. Indeed, in case of unwanted events happening, our design ensures that the whole structure remains safe and won't break. Wheels will only be used for movement if the friction is enough to drive the parts.

For each moving part, we installed 4 electric motors symmetrically positioned on the structure. The symmetry is also a very important aspect to ensure the free rotation of each part.

Indeed, to apply the enough friction force, each motor is using a spring that ensure constant contact pressure of the wheel and the movable part.

The top layer and bottom layer are spinning in opposite direction which helps to cancel the resultant torque on the central part and then helps to decrease installation movement during acceleration or deceleration phase of the rotation. The controllers of the motors have also been programmed to start and stop gradually to ensure smooth acceleration of transition phases. After the acceleration phases, the rotation speed is constant and ensures stability of the overall structure.

3 ⁄ 环保表皮

Sustainable Cladding

The façade design was inspired by the “Green Net Regeneration” eco-concept proposed by the architectural team PILLS. This project represents a sustainable practice of transforming waste materials into exhibition pieces and has provided bespoke. with valuable experience in exploring sustainable materials.

The concept of “Recycled Construction Safety Nets” involved the design team collaborating with 11 architectural firms nationwide to collect used green safety nets from construction sites across different regions. These nets were used as the core material of the installation, fully embodying a closed-loop material cycle of “waste–design–exhibit.”

From a design perspective, these green nets retain traces of their original use and natural fading, which not only reflects the eco-friendly principle of recycling but also carries the cultural memory of specific regions and eras, creating a highly expressive localized expression. We worked closely with the architects and fabrication team to thoroughly study the material properties, ensuring their presentation within the structural installation is both authentic and full of dynamic tension.

PILLS believes that “viewers can catch glimpses of the story through the perforated patterns from outside, which draws them in and naturally leads them to step inside the installation. Beneath the ‘Vault of Heaven,’ they fully immerse themselves in a dynamic narrative through looping visuals, experiencing the Chinese imagination and longing for a better life.”

4 ⁄ 精密制造

Precision Build

The fabrication of the installation has been based on a fully detailed 3D model. Each element was modeled precisely in 3D and all 2D drawings were extracted from the model. Each part was laser cut and welded together.

The whole structure had then been pre-assembling together in factory to ensure all components fit together. Some adjustments were made during the fabrication and pre-assembling to optimize and ease the installation which happened later on site in Venice.

Fabrication was done by UAP Shanghai, in their new Qidong factory workshop. bespoke. team went there several times to ensure fabrication progress and quality control.

The whole process including structure design, fabrication and preparation for transportation has been done in less than one month. bespoke. team also helped to follow and guide the installation in Venice at the Arsenal. Thanks to the good preparation and all the work that has been done in advance, installation with local and Chinese team in the historical went well and was accomplished within few days.